What is Cable Railing?

Cable railing is an alternative fall protection system used in place of wood or metal balusters. Any cable railing system consists of several rows on tensioned stainless-steel cables suspended between posts in a handrail.

Many choose cable railing over traditional fall protection systems for their decks or staircases for its minimalism, and updated aesthetics, as well as it being more cost effective than traditional railing options. If you're looking for a low-maintenance, minimalistic, and cost-effective option for a balustrade, then cable railing is an excellent option.

Elements of a Cable Railing System

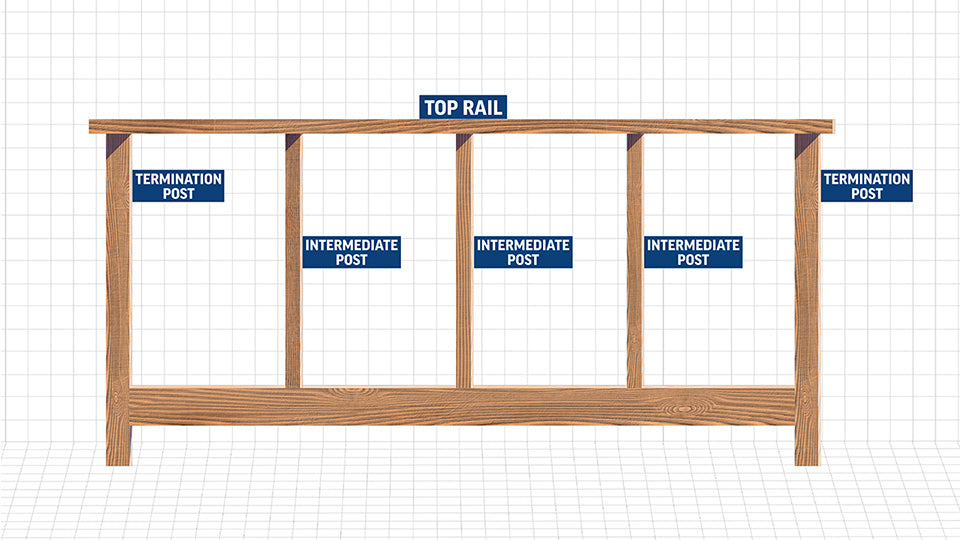

Railing Structure When installing a cable railing system, it’s important to consider the posts and handrail where the cable is going to be installed. Cable railing can be adapted to many new or existing post and handrail constructions., Whether it be all-wood post, metal post, or a combination of the two. Whatever type of post and handrail construction you’re installing cable railing on, you will always have these parts of the system to consider.

Termination Posts, refer to either the “end” or “corner” posts that each end of your cable will attach to. Intermediate posts, that support the cable over the distance that it's traveling, and the top rail or handrail which is required for any deck or staircase.

Termination Posts, refer to either the “end” or “corner” posts that each end of your cable will attach to. Intermediate posts, that support the cable over the distance that it's traveling, and the top rail or handrail which is required for any deck or staircase.

Cable for Cable Railing

Apart from your posts and handrails, a cable railing system is of coursed composed of cable and components. So first let's take about the cable.

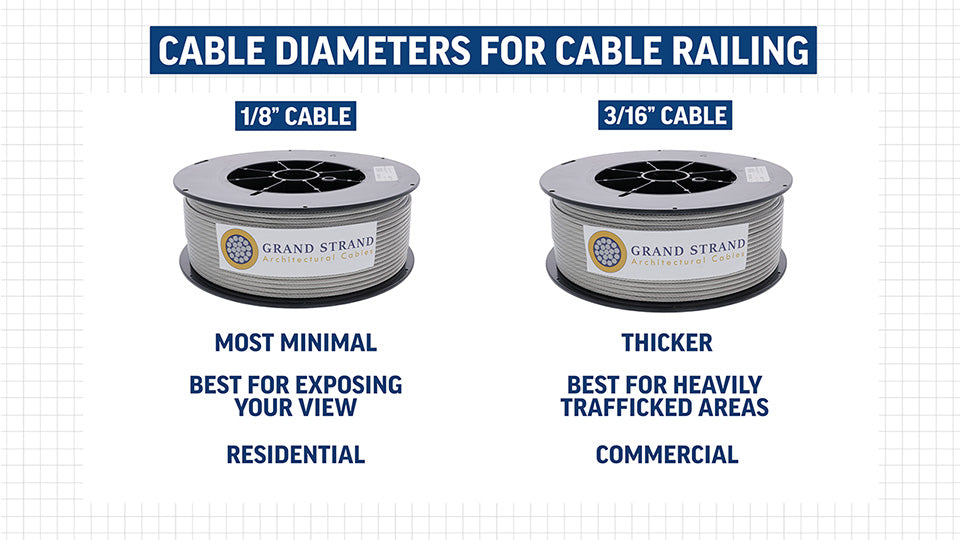

The two most common cable diameters are 1/8” and 3/16”. Choosing between the two is really based on you would like your system to look. 1/8” cable is the most minimal option, it’s great for residential applications and does an awesome job of exposing your view. 3/16” offers a more substantial, industrial look and is popular for both residential and commercial applications.

Apart from the cable diameter, cable construction is probably something you’ll run across. The industry standard cable construction for cable railing is 1x19, since it cuts cleanly, and is a very straight-running, low-stretch cable.

Cable Railing Components

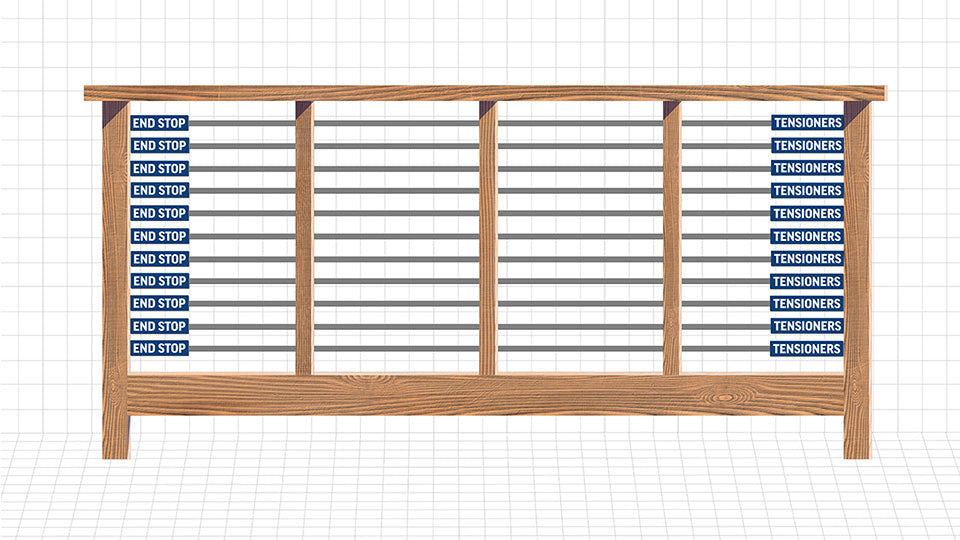

You’ll notice we use the word components in a lot of our videos to describe the different parts that connect to each end of the cable. So, the first component that we will talk about is an end stop.

First, we have end stops. This component’s job is to secure one end of the cable at a termination post. Opposite the end stop, you have tensioners. These components tighten the cables.

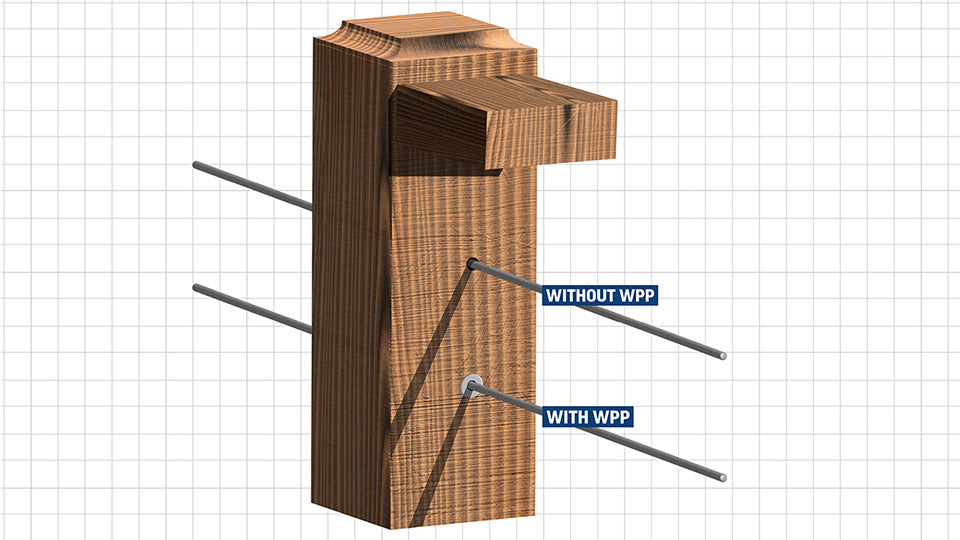

Post protectors are used primarily in your intermediate pass thru post, and sometimes termination posts. They are designed to give your system a finished look and they also protect your post from cable abrasion. While they are optional, we strongly recommend including them into your design to keep your railing looking great for years to come.

Swaging

You might be asking yourself “how do the components attach to the actual cable?”. While the post protectors simply slide on to the cable during installation, the tensioning and end stop components will be permanently joined to each end of your cable through a process called swaging, which is basically another word for crimping.

Swaging your tensioning and end stop components to your cable is done so with a tool called a swager. For more information about swaging, click here

How Do Cable Railing Systems Work?

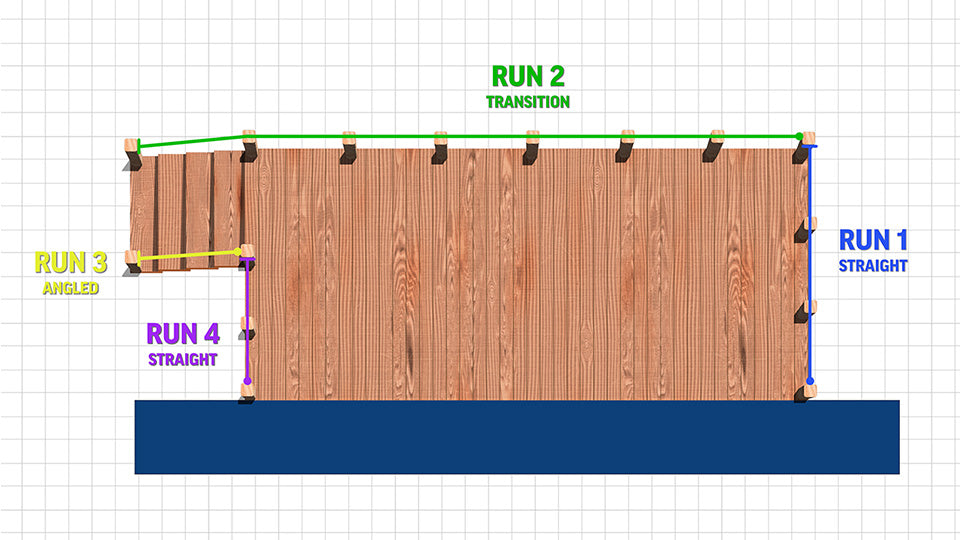

A cable railing system is made of one or more segments called “cable runs”. Each run will consist of rows of tensioned cables that are secured at one end by end stops and tensioned at the other end by tensioners. In most cases, only one side of the run will need tensioners.

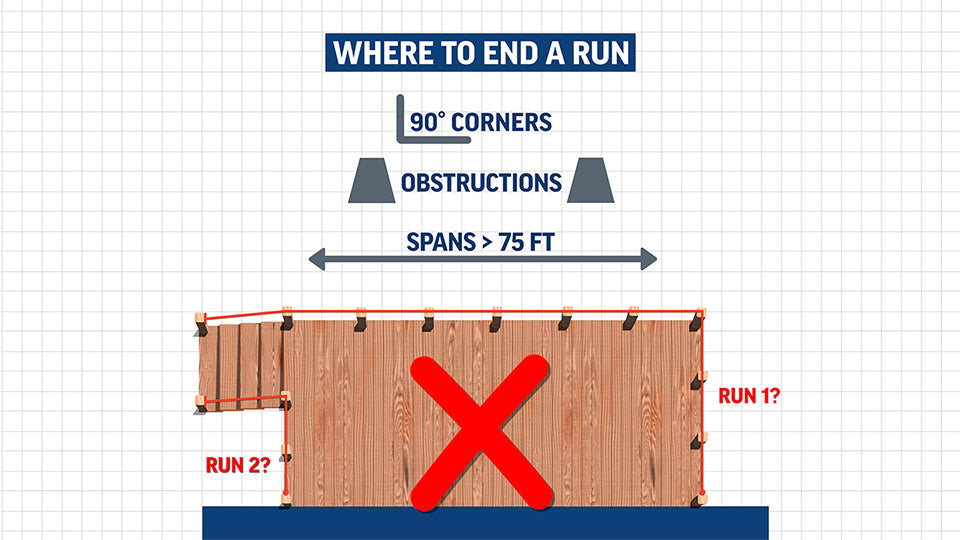

It’s easy to forget that cable rail systems are not continuous. A cable rail system will be broken into runs by factors like 90-degree corners, obstructions like walls or columns, or runs that span more than 75ft.

Types of Cable Runs

When planning out your cable railing system, one of the first things that you'll need to do is identify the types of cable runs that you have.

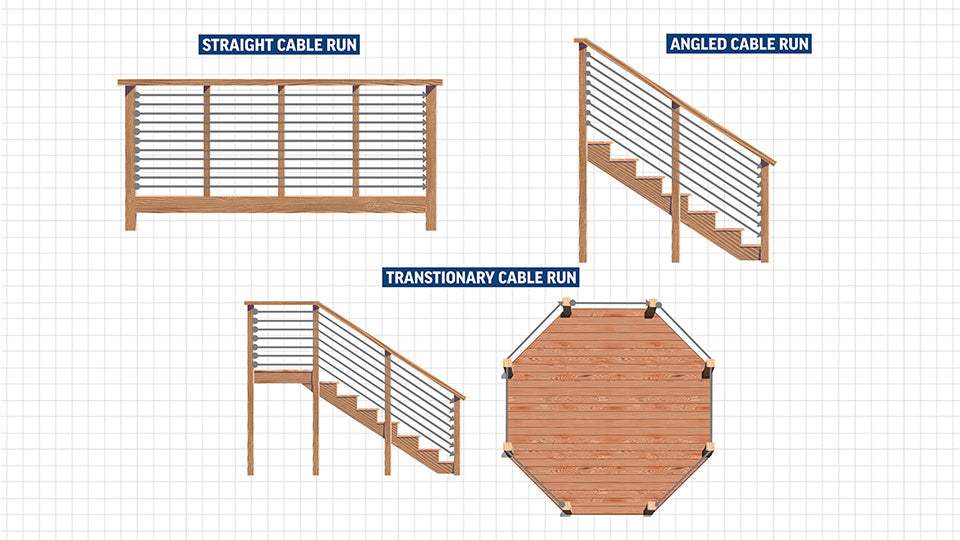

A straight cable run is a type of run where your cable and components will be running straight or perpendicular to both your termination and intermediate posts.

Angle cables runs are typically found on a staircase, where your cable and components will be running at consistent angle from one termination post to another.

The last run we’re going to talk about is a transitionary run. Meaning that, the run starts off at one angle and changes angles at an intermediate post between your termination posts. A transitionary run can transition at a horizontal angle, like this octagonal deck, or transition vertically like this staircase with a landing.

Being able to identify each of these runs in your project will be the first step in planning out your own custom cable railing system.

Where Can I Find More Info?

At HAAS Stainless, we designed and manufacture two cable railing systems in-house. The HAAS REVO and the HAAS AXIS Systems. We’re here to walk you through the ins and outs of installing your own cable railing system. Make sure to subscribe to our YouTube channel here