What Are Rigging Shackles

Shackles are a type of rigging fitting that’s used as an attachment component for lifts or suspension.

NOTE: Refer to ASME B30.26 for all guidelines pertaining to overhead lifting and suspension.

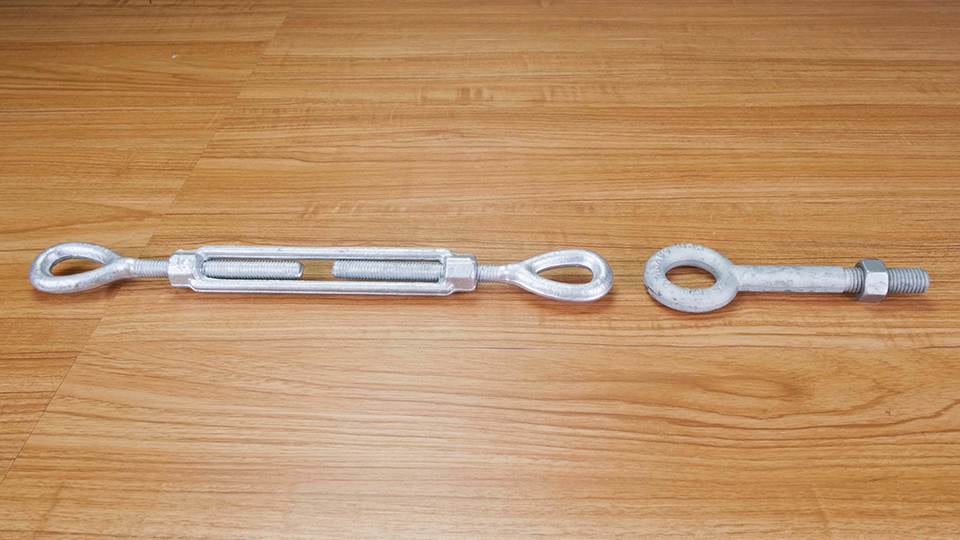

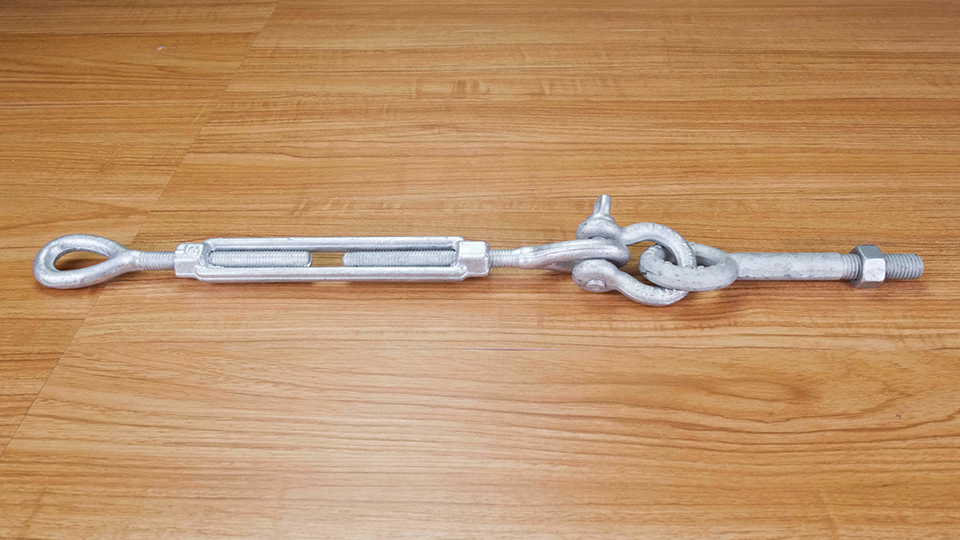

A common example of how shackle would be used is attaching a turnbuckle to an eyebolt. These components are closed making them strong and reliable, however an equally strong link must be made to achieve connection. A shackle is that linking component.Shackle Anatomy

When referring to shackles, it’s important to know that right nomenclature. The “bow” indicates the top or closed end, the “ears” refer to the open end and where the pin slides or screws through, and lastly, the “pin” slides or screws through the ears to close off the connection. Specifications of these parts of the shackle are important to know in the project planning stage. On our site you can find each shackles’ dimensions in their respective product pages to make sure you make the right purchasing decision.Varieties of Shackles

Over the years, shackles have taken on plenty of unusual and often bizarre shapes to best perform in specific applications.

Anchor Shackle

These shackles are the most recognizable and versatile shackles by far. They can be side- or cross-loaded when factoring in load reductions to the in-line working load limits.Bow Shackle

Bow-type shackles technically fall under the anchor category but are used for the bow’s increased radius to prevent a web sling from kinking or bunching during a lift.Chain/D Shackle

The Chain or D-type Shackle is recognized for its slimmer bow, making a “D” shape when held on its side. It’s designed to connect to chain and rated for in-line tension only. When in use, the center of the load should always coincide with the center line of the shackle.Specialty Shackles

Shackle Material and Coating Types

With shackles, one-size will not fit-all, and the same is true for coatings and materials. When selecting a between galvanized steel, powder coated, and stainless-steel it’s important to consider the environment to which your shackle will be exposed.Hot-Dip Galvanized Shackles

Galvanized steel shackles are the most basic, all-around, and cost-effective shackle type. They’re used in most general-purpose applications whether indoors or out in the elements. While corrosion resistance is moderate, many find it easy to inspect and maintain. Most are made with strong steel which attributes a high working load limit.Powder Coated Galvanized Shackles

These black oxide steel shackles are a step above simple hot-dipped galvanized. Many choose these shackles for dynamic rigs and repeated movements since the coating is highly durable.Stainless-Steel Shackles

When corrosion is the main concern, stainless steel shackles are the way to go. While not as strong as steel, they perform well in and around saltwater and other reactive environments. Stainless-steel is the best at resisting corrosion, however it could rust over time, so we strongly recommend maintaining and cleaning this shackle type periodically.Want to learn more about shackles like WLL, dimensions and pin type?

Read more here