1. “How far apart should the cables in my system be spaced?”

National Building Code requires that your cables be spaced no more than every 3”. Most US County codes specifies a 4” cable spacing. However, we recommend always double-checking with your local building inspection office.

2. “How far apart should I space my posts?”

National Building Code is going to state that your post should be spaced so that there's no more than a 6’ gap in between each post. Much like cable spacing, we recommend always double checking with your local building inspection office. Now with post spacing keep in mind the further that you space your post more rigid a cable railing system will be. A closer post spacing is always going to result in a better cable railing system. From a cable railing functionality standpoint, we recommend a maximum post spacing of every 6’.

3. “What is the farthest span that I can run my cables?”

The farthest that we recommend spanning your cable for a straight cable run or a cable run with a single angle change is going to be no further than 75’ when using a single set of tensioning fittings. If more unique solutions are required for cable runs longer than 75’, we recommend setting up a cable railing consultation to talk with one our cable railing professional that will answer any questions about special cable railing scenarios.

4. “How tensioned should my cables be?”

National Building Code requires that cables be spaced at every 3” so that you cannot forcefully push a 4” sphere in between your cables. While not everyone has the resources to apply the 4” sphere test, we recommend going by personal preference or to a set amount of tension that's going to pass building code for your local area.

5. “What should the handrail height be for my cable railing system?”

National Building Code requires handrail heights can be in between 36” and 42” tall. Once again, we recommend always double-checking with your local building inspection office.

6. “Do I have to use cable cutters when cutting my cable?”

Alternative tools like bolt cutters or angle grinders will deform the end of your cable and fray your cable strands making it difficult to nearly impossible to insert the end of the cable into the swage cavity of cable railing fittings. Cable cutters are specifically designed with circular blades that leave you the cleanest cut for a headache-free day on the job.

7. “Will any swaging tool work with the REVO or the AXIS System?”

Cable railing fittings are not designed like other rigging fittings. Attempting to use a regular rigging swager (e.g. swager designed to swager hourglass sleeves/ferrules or buttons) will deform the fitting and will not achieve a strong swage. The result of this is cable swage failure under tension, which is when the cable pulls out of the swage cavity. Cable railing components must be swaged by a swager that is specifically designed to be used with cable railing components. When it comes to swaging the HAAS REVO and HAAS AXIS Systems, you’ll be using the Crenshaw Cable Railing Swage Tool or a swager that we have tested and can recommend from a different supplier.

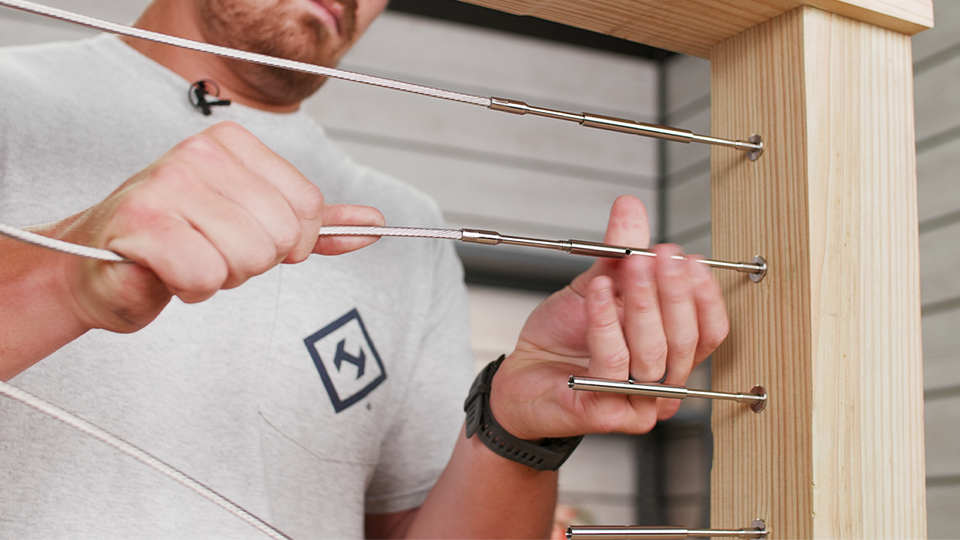

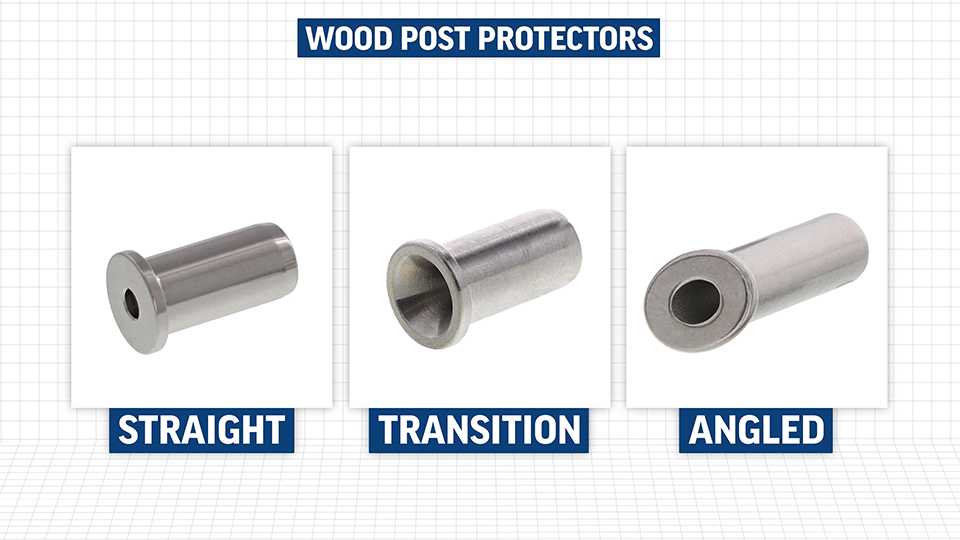

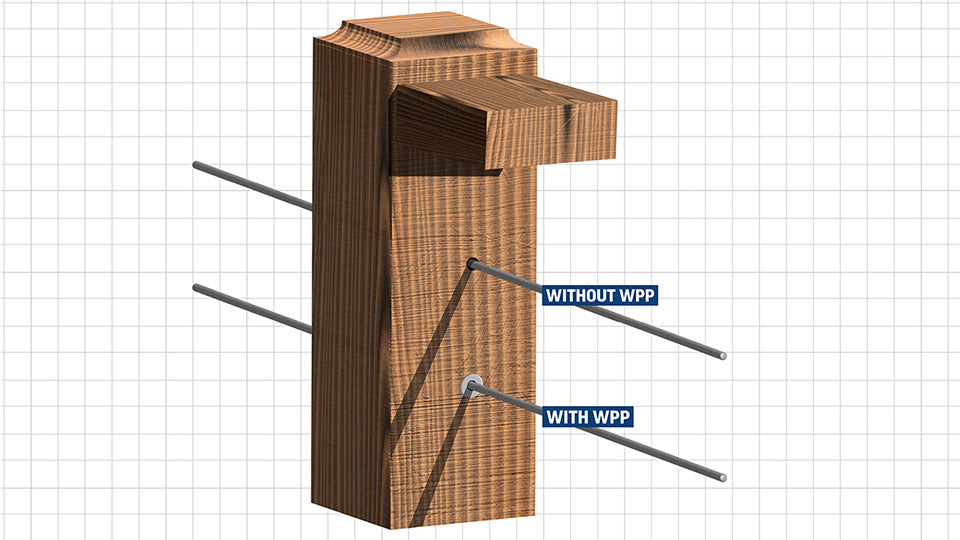

8. “Do I have to use post protectors for my system?”

Post protectors serve both an aesthetic and functional purpose whenever it comes to cable railing. They are, however, optional. If you’re questioning whether post protectors are right for your cable railing system or a specific post scenario, click here to read more about post protectors

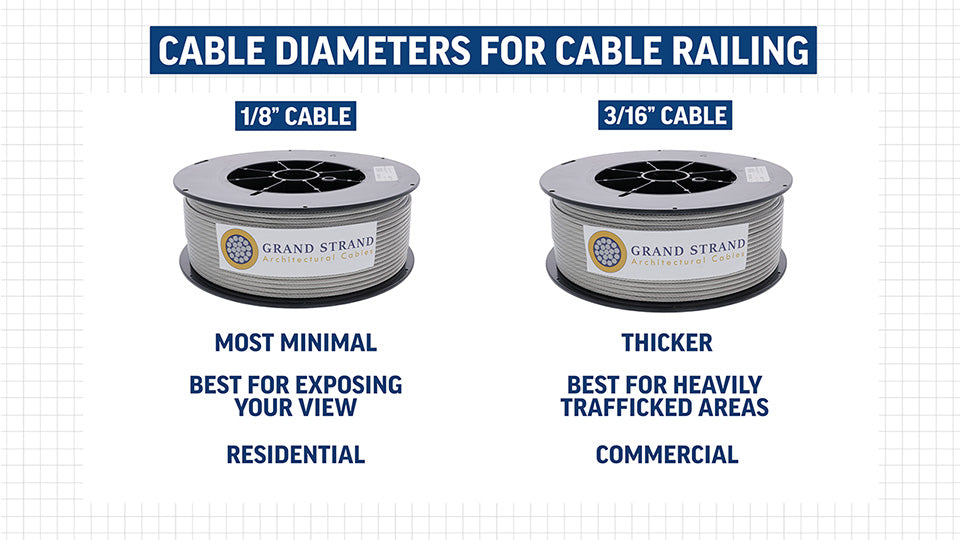

9. “What type of cables should I use for my cable railing system?”

So here it HAAS Stainless. We're going to recommend you use 1X19 Type 316 Stainless-steel Cable in either 1/8” or 3/16” diameter. This cable is very corrosion resistant, rigid, and has little-to-no stretch, making it ideal for cable railing systems.

10. “Do I need to use 1/8” or 3/16” diameter cable for my cable railing system?”

Both 1/8” and 3/16” cable can be used for residential and commercial applications and offer a very unobstructive view. The biggest differences between the two is 1/8” is a little bit lighter and easier to work with and going to feel most minimal when installed. 3/16” is heavy and stiff making it slightly more difficult to work with. It won’t obstruct your view anymore than 1/8”, but it will offer the feeling of more security because of the slightly larger diameter. At the end of the day, it’s about personal preference and what result you’re seeking.

11. “Will the cables in my cable railing system sag?”

Every post and handrail project is constructed differently. From metal, like steel or aluminum, and fine timbers, like White Oak and Ipe, to pressure treated lumbers, they are all variously affected by the elements which can change they’re shape over the lifetime of your system. Whenever it comes to exterior cable railing in metal and hardwood post and handrails, it’s rare to see any sagging or loss of tension unless the system suffers damage. It is, however, totally normal to see some cables come out of tension on cable railing system installed on pressure-treated lumber decks. If you do experience any loss of tension to the cables in your system, then all you’ll need to do is re-tension them as part of your regular deck maintenance.

For additional resources and answers to cable railing questions, click here to visit our Cable Railing Knowledge Base